carbon cnc machining Machining composite materials is a challenging task. Proper tool selection, machine settings and process innovations help make it manageable. Machining of a part-seating undercut in a medium-density fiberboard fixture. . Trust the industry's largest provider of end-to-end wire and cable management solutions for indoor and outdoor applications. Explore Legrand’s Wiremold product line that offers a wide array of power solutions for public spaces. Offer convenient access to electric vehicle charging with Legrand's Networked Level 2 EV Charger.

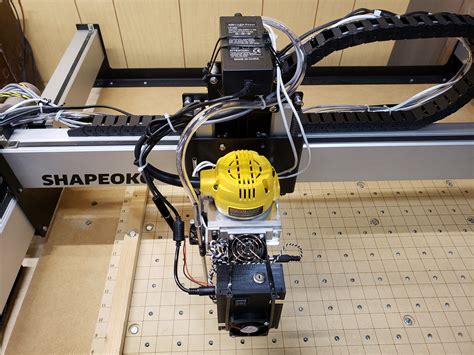

0 · shapeoko cnc official site

1 · desktop cnc for carbon fiber

2 · cnc router for carbon fiber

3 · cnc for carbon fiber

4 · cnc cut carbon fiber

5 · cnc carbon fiber sheets

6 · carbon fiber cnc machine

7 · carbide 3d website

Common Home Electrical Wiring Boxes and How to Use Them: How to Secect The Right Junction Box for Your Electrical Project with Photos and Detailed Descriptions.

Applications of Carbon Fiber CNC Machining. CNC lathes, milling machines, turning centers, and all equipment use Computer Numerical Control to execute the material removal. Subsequently, they can accommodate different . Carbon fiber surpasses conventional CNC machining materials such as aluminum, steel, wood, or glass. It creates high-performance, durable, and low-weight components. . What is Carbon Fiber Machining? Carbon fiber machining involves a series of cutting and fashioning composites of carbon fiber to give you functional carbon fiber components like heat shields and golf clubs. Machining composite materials is a challenging task. Proper tool selection, machine settings and process innovations help make it manageable. Machining of a part-seating undercut in a medium-density fiberboard fixture. .

We utilize both 3-axis and 5-axis CNC machining technologies to cut, mill, and shape carbon fibre materials. Our process ensures high accuracy, maintaining the integrity and strength of the .Machining carbon fiber presents several significant challenges, including tool wear and damage, delamination and fiber pullout, dust and health hazards, heat generation and thermal damage, and achieving a desired surface finish and .

Tech Part d.o.o. specialises in delivering high-quality Carbon Fibre Reinforced Polymer (CFRP) products through state-of-the-art CNC machining and moulding techniques. Our expert team .Elimold provides the best CNC machining services for carbon fiber, ensuring high quality and fast turnaround time. Get custom cnc carbon fiber parts, whether milled or turned parts, or even .

cnc parts store

Read further to learn the most important facts about this material, its features, applications, and how to set up your machine to successfully cut carbon fiber. Samples of carbon CNC machining. What is Carbon Fiber .

Carbon Fiber and Composites have special machining challenges. Discover the tips, techniques, and tooling needed for successful machining. Applications of Carbon Fiber CNC Machining. CNC lathes, milling machines, turning centers, and all equipment use Computer Numerical Control to execute the material removal. Subsequently, they can accommodate different types of tools based on machining requirements. Carbon fiber surpasses conventional CNC machining materials such as aluminum, steel, wood, or glass. It creates high-performance, durable, and low-weight components. Machining carbon fiber sheets is generally accomplished using a router.

What is Carbon Fiber Machining? Carbon fiber machining involves a series of cutting and fashioning composites of carbon fiber to give you functional carbon fiber components like heat shields and golf clubs.

Machining composite materials is a challenging task. Proper tool selection, machine settings and process innovations help make it manageable. Machining of a part-seating undercut in a medium-density fiberboard fixture. Photo Credit: DeltaWing Manufacturing.We utilize both 3-axis and 5-axis CNC machining technologies to cut, mill, and shape carbon fibre materials. Our process ensures high accuracy, maintaining the integrity and strength of the carbon fibre.Machining carbon fiber presents several significant challenges, including tool wear and damage, delamination and fiber pullout, dust and health hazards, heat generation and thermal damage, and achieving a desired surface finish and precision.

Tech Part d.o.o. specialises in delivering high-quality Carbon Fibre Reinforced Polymer (CFRP) products through state-of-the-art CNC machining and moulding techniques. Our expert team and cutting-edge technology ensure precision, reliability, and excellence in every project.Elimold provides the best CNC machining services for carbon fiber, ensuring high quality and fast turnaround time. Get custom cnc carbon fiber parts, whether milled or turned parts, or even tubes, at very competitive prices. Read further to learn the most important facts about this material, its features, applications, and how to set up your machine to successfully cut carbon fiber. Samples of carbon CNC machining. What is Carbon Fiber Laminate? Carbon is a composite material that exhibits excellent strength-to-weight ratio and high-temperature resistance.

Carbon Fiber and Composites have special machining challenges. Discover the tips, techniques, and tooling needed for successful machining.

Applications of Carbon Fiber CNC Machining. CNC lathes, milling machines, turning centers, and all equipment use Computer Numerical Control to execute the material removal. Subsequently, they can accommodate different types of tools based on machining requirements. Carbon fiber surpasses conventional CNC machining materials such as aluminum, steel, wood, or glass. It creates high-performance, durable, and low-weight components. Machining carbon fiber sheets is generally accomplished using a router.

What is Carbon Fiber Machining? Carbon fiber machining involves a series of cutting and fashioning composites of carbon fiber to give you functional carbon fiber components like heat shields and golf clubs. Machining composite materials is a challenging task. Proper tool selection, machine settings and process innovations help make it manageable. Machining of a part-seating undercut in a medium-density fiberboard fixture. Photo Credit: DeltaWing Manufacturing.

We utilize both 3-axis and 5-axis CNC machining technologies to cut, mill, and shape carbon fibre materials. Our process ensures high accuracy, maintaining the integrity and strength of the carbon fibre.Machining carbon fiber presents several significant challenges, including tool wear and damage, delamination and fiber pullout, dust and health hazards, heat generation and thermal damage, and achieving a desired surface finish and precision.

shapeoko cnc official site

Tech Part d.o.o. specialises in delivering high-quality Carbon Fibre Reinforced Polymer (CFRP) products through state-of-the-art CNC machining and moulding techniques. Our expert team and cutting-edge technology ensure precision, reliability, and excellence in every project.Elimold provides the best CNC machining services for carbon fiber, ensuring high quality and fast turnaround time. Get custom cnc carbon fiber parts, whether milled or turned parts, or even tubes, at very competitive prices.

cnc parts store supplier

desktop cnc for carbon fiber

cnc router for carbon fiber

Learn about the wiring diagram for a junction box lighting circuit. Understand how junction boxes are used to connect and distribute electricity for lighting fixtures in your home or building.

carbon cnc machining|cnc cut carbon fiber